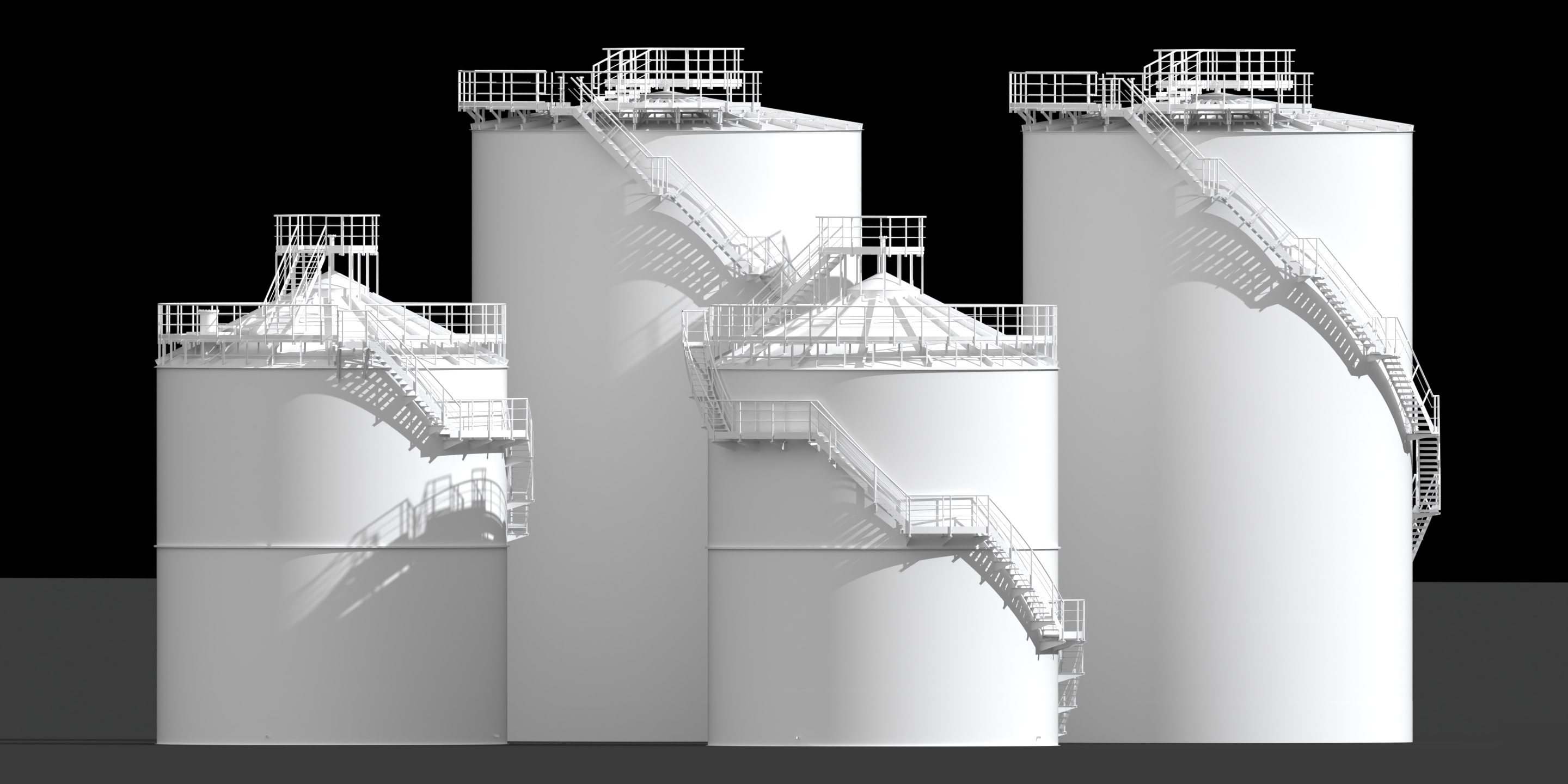

AVL Engineering Bureau offers a complete range of services for the design of storage tanks and vessels. From concept drawings to detailed calculations and fabrication drawings for welded steel tanks, pressure vessels, hoppers and silos used in the petroleum, petrochemical and chemical industries.

OUR SERVICES

- Cone roof tanks (CRT), dome roof tanks (DRT), floating roof tanks;

- Double wall storage tanks;

- Pressure vessels, reactors, towers;

- Heat exchangers, HP&LP heaters, condensers;

- Hoppers, silos, sheet metal steel structures.

- Shells and wind girders;

- Bottoms and different types of roofs;

- Nozzles and manholes;

- Supports and anchors;

- Foundations.

We provide Finite Element Analysis (FEA) for various types of problems during the operational and refurbishment phases of storage tanks and vessels, including but not limited to

- Elastic, elastic/plastic, buckling and dynamic;

- Creep, creep/fatigue analysis;

- Fitness for service assessment per API 579;

- Steel structures analysis.

AVL Engineering Bureau is experienced in working with different standards and codes including but not limited to:

- API 650 Welded tanks for oil storage;

- API 620 Design and Construction of Large, Welded, Low-Pressure Storage Tanks

- API 625 Refrigerated liquified gas storage

- BS EN 14015:2004 Specification for the design and manufacture of site built, vertical, cylindrical, flat-bottomed, above ground, welded, steel tanks for the storage of liquids at ambient temperature and above

- BS EN 14620-1:2024 Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and −196 °C

- ASME (Sec. VIII & III) Boiler and Pressure Vessel Code

- GOST 31385-2023 Vertical cylindrical steel tanks for oil and oil-products. General specifications

- GOST 34347-2017 Steel welded vessels and apparatus. General specifications

THAT’S HOW WE WORK

01. REQUEST

02. OFFER

Get our best offer with detailed scope of work, deliverables, timeline and price

With all the points described, the contract is the basis of our collaboration.

04. CONCEPT DESIGN

Based on Design Specification and applied Design Codes we prepare Design Concept (GA drawing) and technical specifications for work conditions. We plan location and type of nozzles, manholes and other required elements.

05. BASIC DESIGN

Based on strength calculations we define thickness of all main structures (bottom, shell and roof). General assembly drawings show main structures, their connections, plans of nozzles, stairs and platforms. At the finish of this stage you will receive the requirements for interior and exterior painting, bill of materials for all main structures.

06. DETAILED DESIGN

We provide finite element analysis and final calculations for all structural and miscellaneous elements. Fabrication drawings consist of assembly and one part drawings of all elements. Erection drawings provide all information for installation including plans, sections and connection details of all elements. We also provide notes for inspection during the fabrication, construction and operational phases.

BOOK A FREE ONLINE MEETING

Tell us about your project in a free 30 minute online meeting and see how we can help.

Send us your request and get our offer